There are many correction methods after steel plate processing. Manual calibration is carried out at room temperature. Due to cold work hardening, it is only applicable to steel with good plastic correction effect. If the thick steel plate protrudes and deforms in the middle of plate processing, first place the steel plate on the working platform, make the protruding part upward, and apply a certain pressure on the surface of the deformation area. Because the surrounding material has a large stiffness in the plane direction, the stress state of the material in the deformation area is the same as the arch beam bearing the transverse load, which shortens the deformation of the fiber and achieves the effect of leveling.

During the correction of thick steel plate, if the deformation area is not too large, the correction method with larger load should be selected. In the case of large pressure equipment, the equipment should be used as much as possible to reduce the labor intensity of the operator, or the buffer plate can be used to directly hammer the metal plate with a big hammer. Projection of thick steel plate.

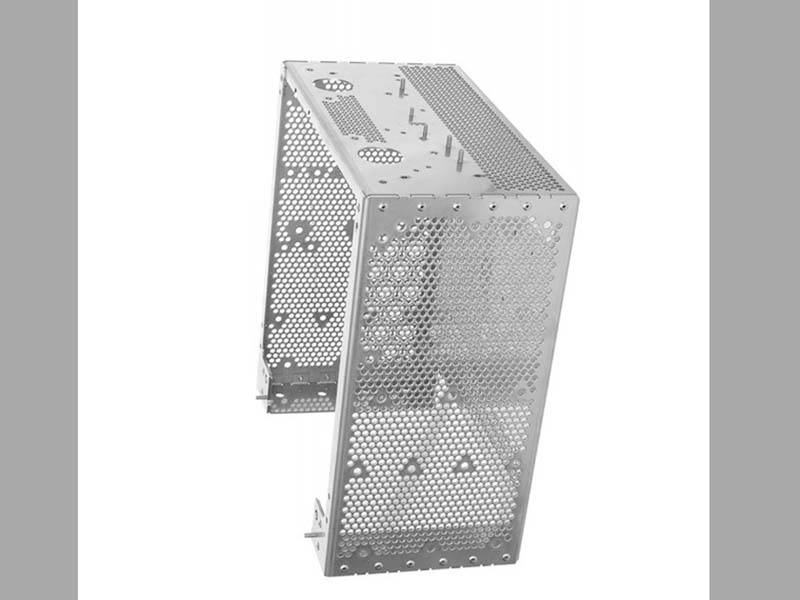

QUICK LINKS:>>> Sheet Metal Frame | Sheet Metal Housing | Sheet Metal Chassis | Metal Kiosk Enclosure | Sheet Metal Cover | Sheet Metal Parts Components | China Sheet Metal Manufacturer | Custom Sheet Metal Parts | Metal Enclosure Manufacturers | Sheet Metal Cabinet | China Sheet Metal Parts | Sheet Metal Bracket | Sheet Metal Parts Manufacturer | Custom Electrical Enclosures | China Sheet Metal Fabrication | China Metal Parts Manufacturer