Read Time:38 Second

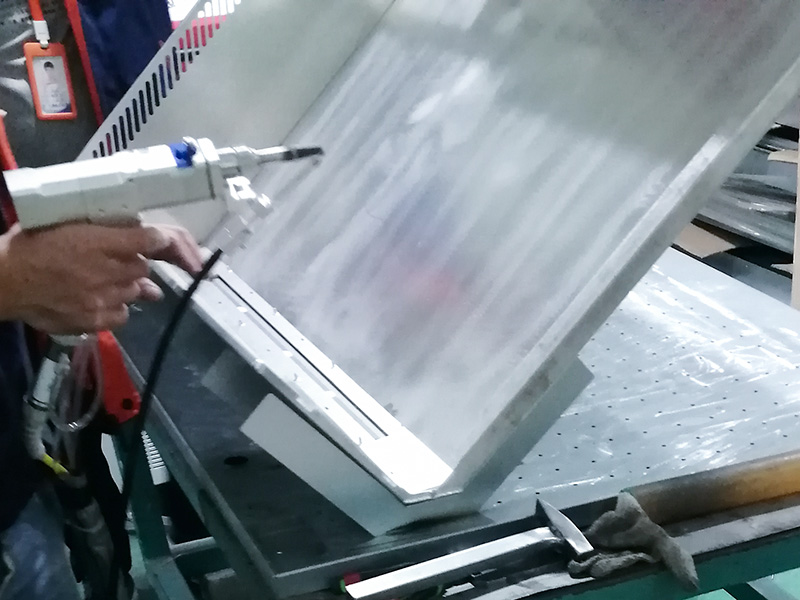

- Consider whether the cutter of the bending machine meets the requirements of drawing paper R.

- It depends on whether the cutting tool or fixture of the bending machine blocks the position of the next bending.

- Check whether the bending tool and fixture have just rubbed and collided after the last bending and this bending.

- See if the last one to be bent rubs and collides with the bending tool and fixture.

- See whether the dimension of the last bend can be used as the positioning benchmark of the next bend.

QUICK LINKS: FAQ | Sheet Metal Parts Pricelist | Galvanized Corner Brackets | Corner Joist Bracket | Rapid Sheet Metal | Prototype Sheet Metal | Sheet Metal Parts | 80 20 Corner Bracket | Customized Wholesale Bottom Plate | |Battery Mounting Bracket| Custom Rack Panels

About Post Author

Yan yifan

One of China's Experienced Sheet Metal Manufacturer and Fabricator Since 2011.