6 Types of Bending and Forming of Custom Sheet Metal Boxes

Bending forming of sheet metal is when the sheet metal first goes through elastic deformation and then enters plastic deformation under the pressure of the upper or lower die of the bending machine. At the beginning of plastic bending, the sheet is free to bend. With the pressure of the upper die on the plate, the plate and the lower die V-groove surface gradually tighten, while the radius of curvature and bending force arm also gradually become smaller. Continue to press until the stroke is terminated, so that the upper and lower die and the plate are in full contact at three points, at which time a V-bend is completed and a bend is formed.

Common Ways of Sheet Metal Bending

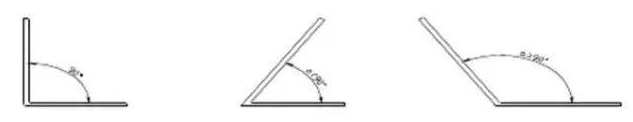

(1) L-bending

L-bending is divided into 90°bending and non-90°bending according to the angle, which is named according to the angle within the bending. 90°bending deformation factor is 0.4 times of the material thickness.

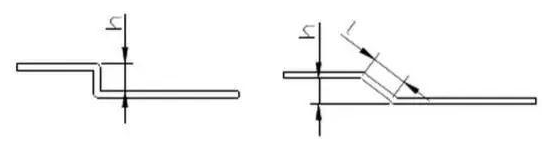

(2) N-fold

N-fold forming according to the value of l and h size and take different processing methods, one is directly divided into two fold molding, the other is to add shims backfold flat, in general, N-fold in the H for the more important size.

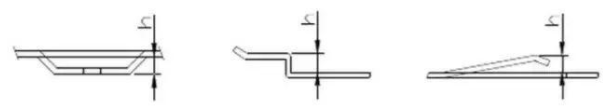

(3) Z-fold

Z-fold, also known as a break, according to the forming angle is divided into straight edge break and beveled edge break, processing method according to the height of the break, straight edge break when the break height h is less than 3.5 times the thickness of the material using a break die or easy die forming, more than 3.5 times the thickness of the material using a normal positive and negative two fold to complete. Beveled edge break when the beveled edge length l is less than 3.5 times the material thickness, using the break difference mold or easy mold forming is greater than 3.5 times the material thickness, using the normal one positive and one negative fold to complete

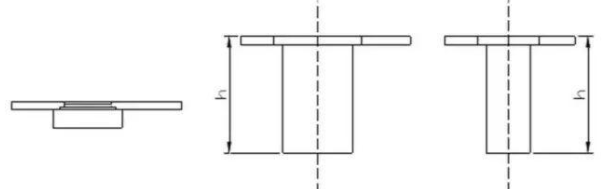

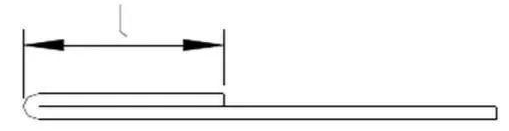

(4) Pressing the Dead Edge

Pressing the dead edge, also known as reverse folding and flattening, its forming process is completed by two steps; first bending to about 35 degrees, this step is the insertion depth, and then pressed out the dead edge with the flattening die. Operation should pay attention to the parallelism of the large surface after forming.

(5) Riveting

Using the folding bed for riveting operations generally need to jig to ensure the verticality of the rivet, jig structure is similar to the riveting machine under the mold.

(6) Easy Mold Forming

Small breaks, small snap hooks, shrapnel, draw bridges, etc. using the bending machine ordinary mold can not be completed or the processing process is more complex, then the bending machine can be designed to complete the processing of easy mold action.

Many types of CNC bending machine in actual use according to the specific requirements of the plate bending! click sheet metal supplier to learn more information to custom sheet metal boxes